Revised 8/8/13

|

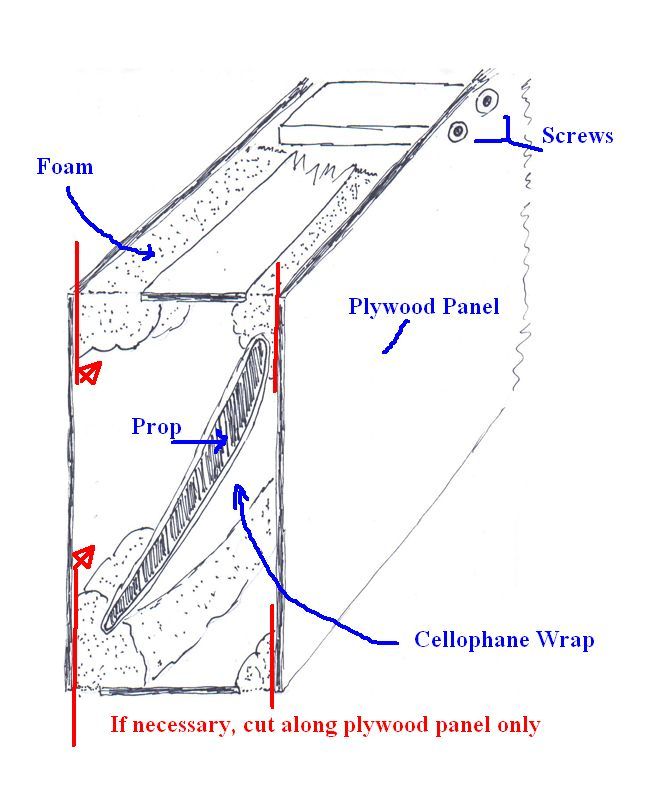

UNCRATING THE PROPELLER

The propeller covered in cellophane wrap, suspended in the center of the plywood shell by a wooden bar, held in place with foam insulation to hold it securely, then covered on the sides with thin plywood held on by sheetrock screws and sometime additional plastic banding. You can save the box itself and chunks of foam for possible re-shipment, including return.

Check carefully for signs of external damage that may have been caused by the shipping company and notify them immediately if there is any concern. To unwrap it do the following:

1. Remove black sheetrock screws (and tape, if present) from plywood faces, including the central screws that hold the hub. You can leave the nickel coated screws (except at the ends) in place, as panels are sometimes glued beneath those screws. Remove wooden end pieces and widest plywood panels. They may need to be gently hammered away from the propeller or carefully cut along the plywood edge (see #3, below). The foam is easily separated from the cellophane around the propeller.

2. Get a large trash can or plastic bag for debris.

3. Peel plywood away from the foam, or gently peel foam away from the cellophane in places where the foam sticks too hard to the plywood. A SMALL (i.e. 2") paring knife may be helpful if large surface areas of foam are stuck to the wood, but be sure to use it ONLY against the WIDE plywood surface, not the propeller or the narrow plywood piece (see photo and diagram).

4. Unwrap or gently tear the cellophane wrap from the propeller surface.

5. For international shipping VIA AIRLINE, a marked panel will indicate the preferred panel to remove for inspection. The foam has been gently cut along its edges to allow the carrier to inspect the cargo before loading on a passenger plane. This does not seem to be necessary when shipped via FedEx, etc.